Plastics to pavement – Closing the Loop on soft plastics at Deakin

Soft plastics account for approximately 25 tonnes of Deakin’s waste to landfill each year and include items such as shrink wrap, plastic bags, and food wrappers.

With Deakin committed to working towards zero waste to landfill by 2030, we must limit soft plastic coming onto our campuses by working with our suppliers to avoid waste and by diverting any soft plastic waste to recycling and circular economy opportunities.

In 2020, Deakin used Reconophalt to build the 350 meter Nicol Drive North road extension at the Waurn Ponds Campus – this stretch of road included 165,000 plastic bags/packaging equivalents, toner waste from 3,700 toner cartridges, and 41 tonnes of reclaimed asphalt. Deakin has also specified Reconophalt for the Epworth Place Roadway Extension and our Design Standards have been updated to include sustainable asphalt products for other future road works.

As Deakin is now a buyer of recycled soft plastic within the circular economy, we have unlocked a unique and sector-leading opportunity to partner with Close the Loop and recycle up to 25 tonnes/year of Deakin’s soft plastics for use in sustainable asphalt.

> The initiative

Soft plastics account for approximately 25 tonnes of Deakin’s waste to landfill each year and include items such as shrink wrap, plastic bags, and food wrappers. With Deakin committed to working towards zero waste to landfill by 2030 by applying circular economy principles, Deakin’s use of sustainable asphalt product Reconophalt has offered a sustainable, circular and effective solution to reducing this waste stream.

In 2020, Reconophalt (a Downer product) was used to build the 350 metre Nicol Drive North road extension at the Waurn Ponds Campus. The asphalt used in this stretch of road included 165,000 plastic bags/packaging equivalents, toner waste from 3,700 toner cartridges, and 41 tonnes of reclaimed asphalt (see video).

Choosing Reconophalt enabled Deakin to establish a unique and sector-leading partnership with Close the Loop, the Melbourne based recycler who provide the recycled soft plastics as an additive for Reconophalt. Through this partnership, the University can recycle up to 25 tonnes/year of soft plastics for use in sustainable asphalt, which can then be bought back for use on-campus. Deakin has now also specified Reconophalt for the Epworth Place Roadway Extension and Deakin’s Design Standards have been updated to include sustainable asphalt products for other future road works.

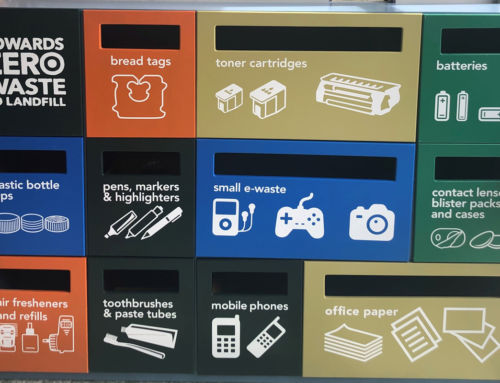

While implementing the new soft plastics collection and recycling program, Deakin conducted a comprehensive review of soft plastic waste within the logistics warehouses (mail and incoming goods), School of Nursing simulation centres, and the Institute of Frontier Material (IFM) labs. This identified a range of soft plastics and other items to be recycled through the program. From the School of Nursing alone, 84,000 latex and nitrile gloves will be diverted from landfill each year. As the success of the collections from these locations are proven, Deakin will expand the soft plastics collections to other areas of the University.

> Environmental and social benefits

Overall, the key impacts from this initiative are:

- Implementation of soft plastics recycling at Deakin, enabling a reduction of up to 25 tonnes of soft plastics from being sent to landfill each year.

- Lower embodied carbon within the sustainable asphalt product.

- Improved performance of asphalt surfaces at Deakin from using the sustainable asphalt product.

- Demonstration of true circularity within waste management, by recycling Deakin’s soft plastic waste and buying back the sustainable asphalt products for use on campus.

- Supporting jobs and the ongoing business of a leading local circular economy-based organisation

- Providing an example project that could be replicated by other organisations that construct roads and pathways e.g., Councils, other higher education institutions. healthcare sector by Deakin’s nursing graduates.

> Leadership and engagement

Deakin is one of only a few organisations that have established a circular economy-based partnership with a soft plastics recycler. Enabled by strong internal collaborations, robust systems for collecting soft plastics, and a commitment to buy back the product in the form of sustainable asphalt, this initiative exemplifies the leadership and business models needed for the circular economy to be successful.

> Wider societal impact

Without organisations buying products containing recycled content, nothing gets recycled. Deakin’s initiative demonstrates leadership in relation to the circular economy, and the use of soft plastic waste within sustainable asphalt.

This initiative demonstrates the possibilities for recycling soft plastics in an authentic, local, and practical way. It also demonstrates the power of partnerships to achieve great circular economy outcomes for difficult to manage waste streams, by committing to buy these back in their recycled form – this is an approach that we are advocating for others to adopt.

The initiative has also created translatable learning opportunities for students in Deakin labs. For example, students within the School of Nursing simulation labs participate in and observe sustainable waste management practices relating to a range of common medical products that are made from, or packaged in, soft plastic. Not only does this instil Deakin’s Sustainability Value and increase awareness of sustainable waste management practices, but it also creates teaching and learning opportunities that can be translated to the healthcare sector by Deakin’s nursing graduates.